Compost turner TG 301

The mechanical roller drive, the cost-effective alternative

Working width: 3.0 meters

Ideal for field edge, small site composting and organic farms with composting up to 8'000 tons per year.

- Conversion capacity up to 700 m³/h.

- Small machine; the TG 301 is only 3.9 m long.

- Low maintenance costs, simplest maintenance.

- Easy handling, simple operation.

- The massive arch construction of the tunnel made of 6 mm steel achieves a very great stability, has no weak corner points and the Powder coating prevents corrosion.

- All wear plates are made of chrome steel.

- Robust, balanced transfer shaft that properly transfers the material to be composted (from the inside to the outside).

- Fast aerobic composting; within 8 - 12 weeks, depending on the material.

- Large wide tires and thus little ground pressure.

- Thanks to swiveling side weight; protection of field and field paths and optimal weight distribution.

- This reduces the total weight of the machine up to 1,500 kg.

- Large Support wheel of the transfer tunnel. Swiveling without tools and in seconds. (The road transport with the wheel swung back is possible without any problems).

Many options retrofittable such as:

- Simple fleece undercutting; eliminating the heavy manual labor of wet fleece.

- Side offset (skew the tunnel to keep the rent where you want it.

- Complete irrigation system.

- and more

Compost Turners

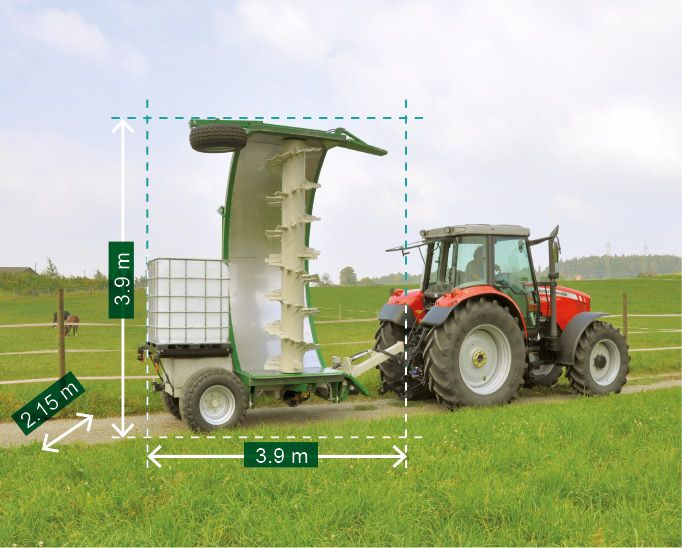

Technical data TG 301

- Conversion rate up to 700 m³/h

- Conversion shaft width 3.0 m

- Total width in transport position 2.15 m

- Total length 3.9 m

- Tunnel height inside dimension 1.65 m

- Total height (Support wheel swung away, transport position) 3 m

- Ideal working speed 300 - 400 m/h

- Weight (basic equipment) 3,700 kg

- Rent width x height 3.0 x 1.5 m

Prerequisites for the tractor

- For tractors with total width up to 2.5 m

- For tractors with min. 80 hp or stepless

- For tractors with a super creeper gear: driven in 1st gear between 300 - 400 m/h at 540 rpm at the PTO

- If the tractor drives faster than 400 m/h, a drive axle (optional) must also be ordered

- Working pressure of the tractor 200 bar

- The tractor needs for the standard version of the TG 301 a double acting valve with float position (these are two plug-in couplings)

Basic equipment TG 301, mech. version

- Cardan shaft with shear bolt

- Cardan shaft Gearbox reduction shaft

- Tunnel with chrome steel plates

- Direct drive on transfer shaft

- Large support wheel on the outside of the tunnel (swivelling, for transport)

- Mechanical feed plates

- Braked axle, with parking brake

- Wide tyres 19.00-45/17 AW

- Rear weight

- Side weight (swivels automatically with tunnel lowering)

- Stone protection rubber left

- Front trailer coupling: DIN towing eye

Options for TG 301

- Towing eye with flange K80 Surcharge

- Towing eye R50 (Hitch) Surcharge

- Hydraulic side weight

- Blade right hydraulic

- Hydraulic side offset

- Hydraulic articulated drawbar with locking block

- Irrigation pipe at front with flapper nozzles (7 pcs.)

- Water connection on rear weight from tunnel

- Drawbar as original equipment

- Vibration damper drawbar

- Wide distributor with Storz connection

- Swivelling light on side weight

- Swivelling drawbar

- Drive axle

- Hoses for external water intake

- Tile guide front and rear

- LED lighting system

- Stone protection rubber right

- Rear hitch

- Control panel for section valve

- Section valve (tunnel + 1x DW)

- DW extension section

- Water pump valve with flow regulator

Various irrigation options:

Country specific options:

- Hydraulic trailer brake

- Compressed air system

- Lower hitch with articulated drawbar mechanical